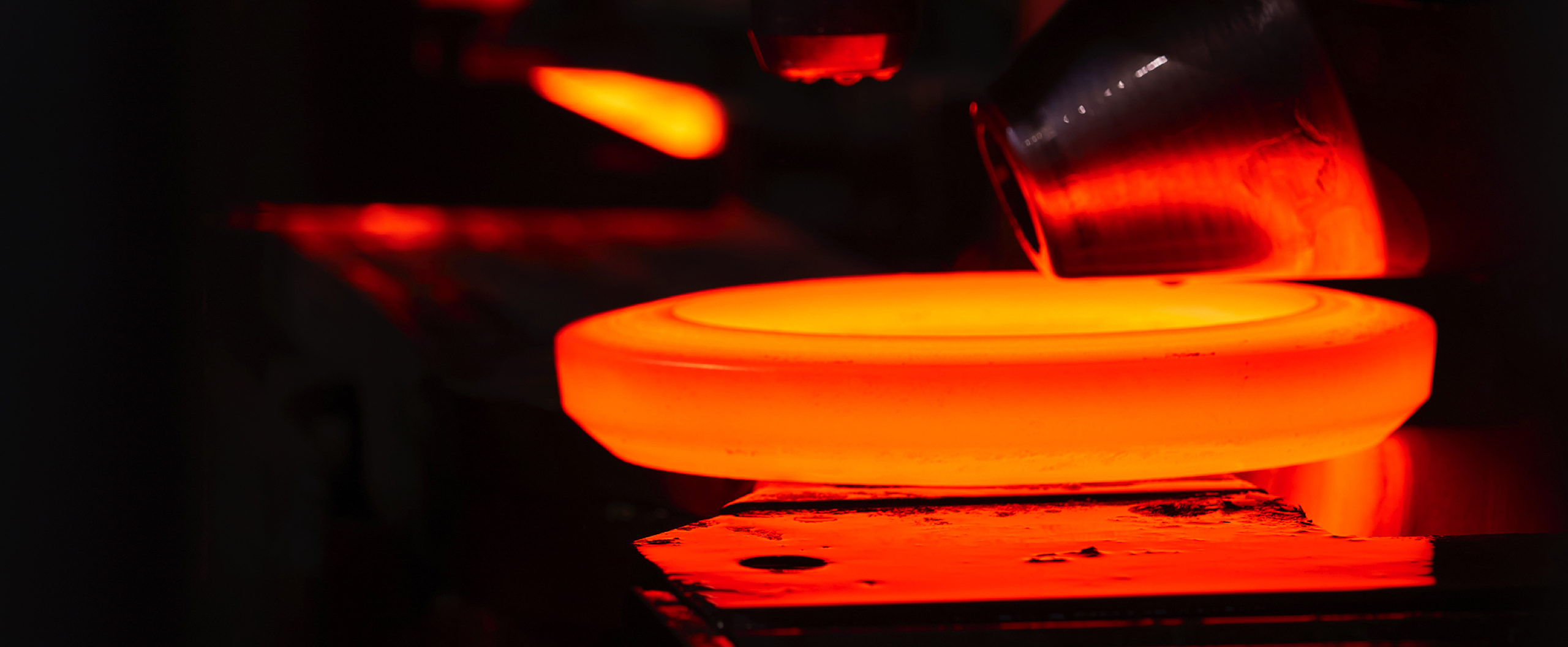

Melting iron and pouring it into shape is universally known as casting. It is relatively easy to make iron sheets and other complex shapes; however, the drawback is that they crack easily.

Where does the strength come from in forging? Japanese swords or well-sharpened kitchen knives are not forged by means of melting. They are beaten by a hammer and manufactured so that the desired shapes is reached.

This is a time consuming but necessary process to ensure the perfect quality of the metal and sturdiness of the part. Our unyielding metal is produced by steady forging throughout production.

We have a history of constantly thinking about our process and how to change it to solve our customers’ problems, and as a result, we have developed our own unique technological capabilities.

“How to manufacture commercial parts with high quality and cost efficiency?”

“How to achieve this in a short period of time?”

Our company-wide focus on these issues has led to our current strengths.

For example;

-All current parts can now be made by forging alone.

-Parts that used to be made separately can now be made in a single piece

(integration of multiple parts).

By doing so, we are able to see beyond the imagination of our customers and make proposals to them.

Specifically, we are good at the following;

- 01.

It is possible for us to design and produce parts even without drawings, as long as there is an actual product (we can even deviate from its original form). - 02.

We handle the entire process in-house, from proposal design, mold making, prototype production, to mass production. - 03.

It is possible to forge a shape with the same precision as the casting method, with all the strengths of our forging techniques - 04.

Our environmentally friendly cold forming technique works by eliminating the formation of any coating such as zinc phosphate film (bondellite). - 05.

Precision forging is possible even in small lots. This can contribute to cost reduction. - 06.

We are particular about inspection accuracy to minimize losses.

Our staff have wealth of experience and technology at their disposal, and also faculties including inspection machines of which there are only a few dozen in Japan.

This is how we improve production efficiency and exceed customers’ expectations.

Our Technology

Our Technology